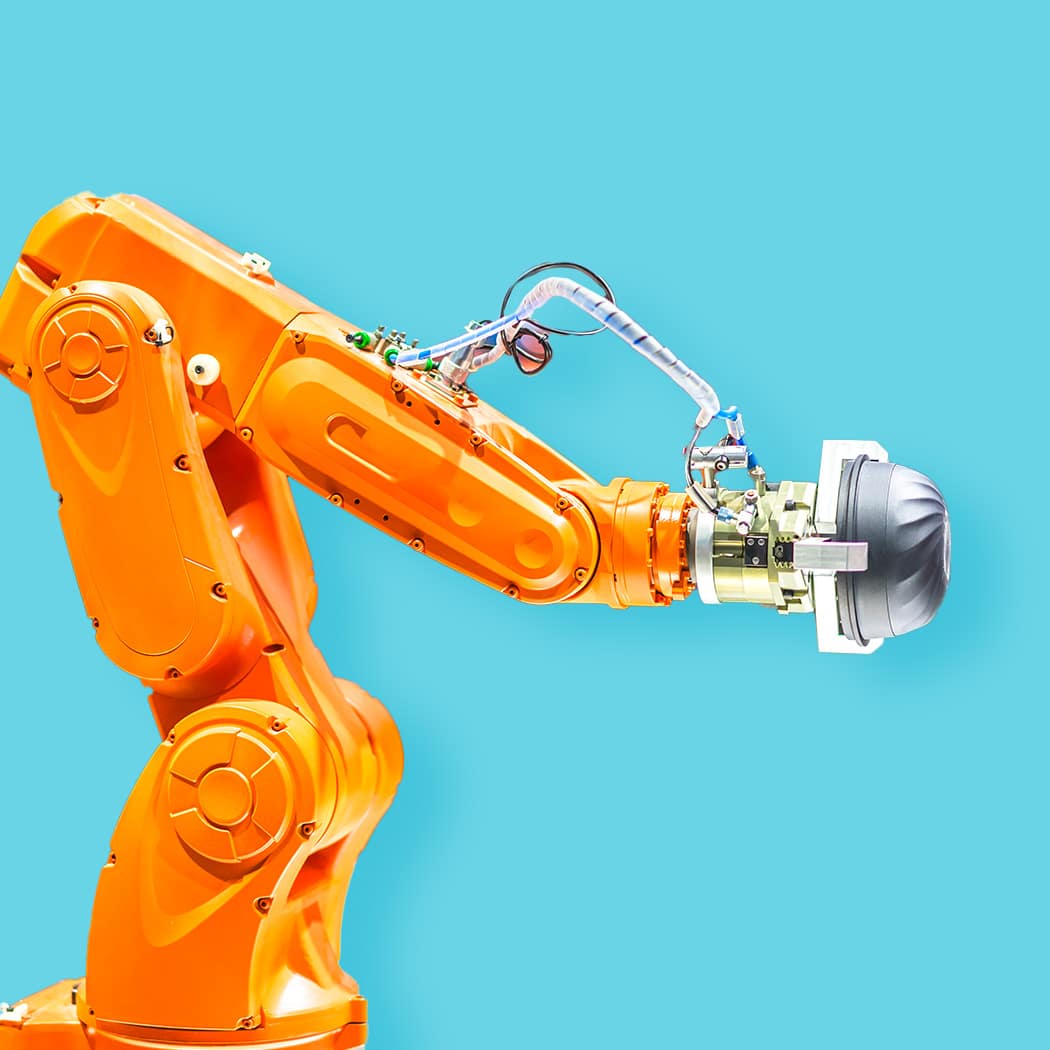

Industrial equipment labeling challenges :

Labeling machinery enables a manufacturer to ensure the traceability and identification of their machinery production. They need to tag these items with the batch number, reference, and date of manufacture. Throughout the manufacturing process, the data must remain legible to guarantee a perfect production workflow and a live update of stocks (parts, components, and finished products).

These robust pieces of industrial engineering work in a stringent environment, so the ink type and the label stock must guarantee a durable print.

Thermal transfer is the most suitable printing technology for a challenging industrial environment, thanks to the robustness of the printer and the durability of the printed labels.

End-users of industrial machinery:

The production, maintenance, and cleaning services must identify all the parts of the machines running in their plants. Identifying the equipment and its parts allows them to take action quickly on machines in the case of a failure. The industrial marking also includes all the instructions or warning logos that enable people working on the machines to take necessary precautions.

Applied to equipment and individual parts, industrial labels are often associated with software that allows them to be registered.

These labels must be clear and legible. In addition, the information on the label must not fade and must last throughout the machine’s life cycle.

Some industrial machinery in harsh environments must be marked with more durable label stock and ink to ensure legibility.

Examples of elements that industrial marking labels must be able to withstand:

- Rubbing

- Chemicals and cleaning products

- Very high temperatures

- Spraying of molten elements

- Hazardous Products

- High speeds

Warning logos

The risks associated with industrial machines are numerous and of different types. Operating errors are unforgiving, and the consequences of accidents are often dire. Therefore, every machine with a risk related to its use or handling must be marked with a warning label. These labels, which must be visible, often take the form of colored logos.

Depending on the nature of the risk, there are different logos:

- Pictures

- Material

- Shape

- Colour

- Marking

- Finish and fixing

All these choices contribute to warning logos functionality: security, information, location, identification, traceability, etc..

Industrial machinery and equipment labeling requirements

In Europe, the CE marking indicates the conformity of machinery and equipment with the health and safety requirements of the European directives. Therefore, the CE marking must be legible and properly affixed to all relevant products to be marketed within the European Union.

There are also US standards that specify requirements for both manufacturers and machine users:

- This is the ANSI B11 series, which consists of numerous documents dealing with machinery and equipment safety.

- In addition to the ANSI B11, the Occupational Safety and Health Administration (OSHA) has developed other standards for:

- The control of workplace hazards

- Lockout/Tagout- Machine Guarding Standards

These standards or requirements often imply the label equipment and industrial machinery with warning logos on parts.

Why using thermal transfer technology for this application ?

Thermal Transfer technology within industrial machinery

Therefore, thermal transfer ribbons are the most suitable solution for labeling industrial machinery. Indeed, the sharpness and permanence of thermal transfer printing make it possible to meet all the needs and performance constraints required by this sector. The customer can find within the ARMOR range resin ribbons that are the most suitable for this type of application. These ribbons are developed to meet the harsh conditions that industrial labels face.

For this application, we recommend the following products:

- AXR 7+: The most representative resin ribbon on the market, offering to ribbon users an outstanding performance in terms of print quality and print durability.

- AXR 8: Users can find an excellent resistance to solvent and high temperature.

For this application, we recommend the following products: